Mixel provides professional finite element technical services. Through numerical simulation technology and optimization algorithm, it enables the product design and development of enterprises, improves product performance and reduces R & D costs.

Mixel has a group of experienced professional technical engineers involved in mechanics, machinery, materials, fluid mechanics and other fields. They have rich theoretical knowledge and practical experience in their respective professional fields. They work together with enterprises and national platforms to solve technical problems in the process of product development, and are highly recognized by customers.

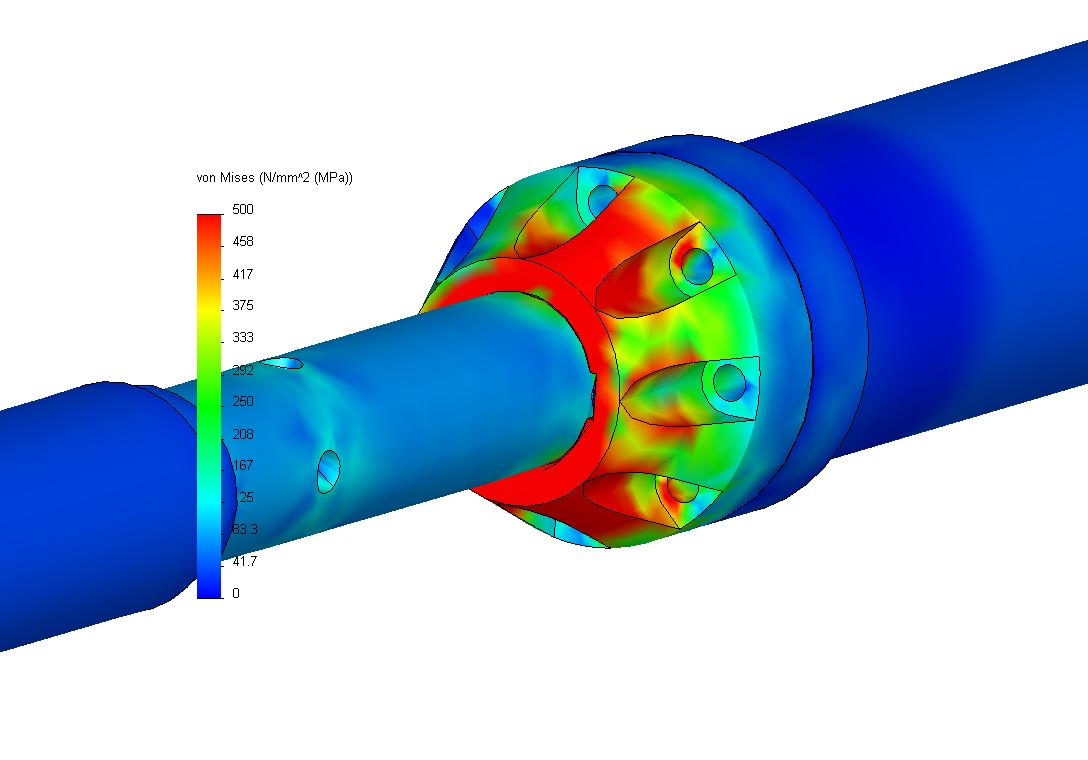

Finite element analysis (FEA) simulates the real physical system (geometry and load conditions) by using mathematical approximation. By using simple and interactive elements, we can approach a real system with infinite unknowns with a finite number of unknowns. In engineering practice, the integrated application of finite element analysis software and CAD system has made a qualitative leap in the design level, mainly in the following aspects:

1. Reduce design cost;

2. Shorten the R & D cycle;

3. Increase the reliability of products and projects;

4. Adopt optimized design to reduce material consumption or cost;

5. Discover potential problems in advance before product manufacturing or engineering construction;

6. Simulate various test schemes to reduce test time and funds;

7. Analyze and correct mechanical failure cases.