2025-07-02 14:11:53

Fumed Silica Liquefaction Reactor | Typical Application of Agitator with Counter-rotating Twin Movement in High-viscosity Materials

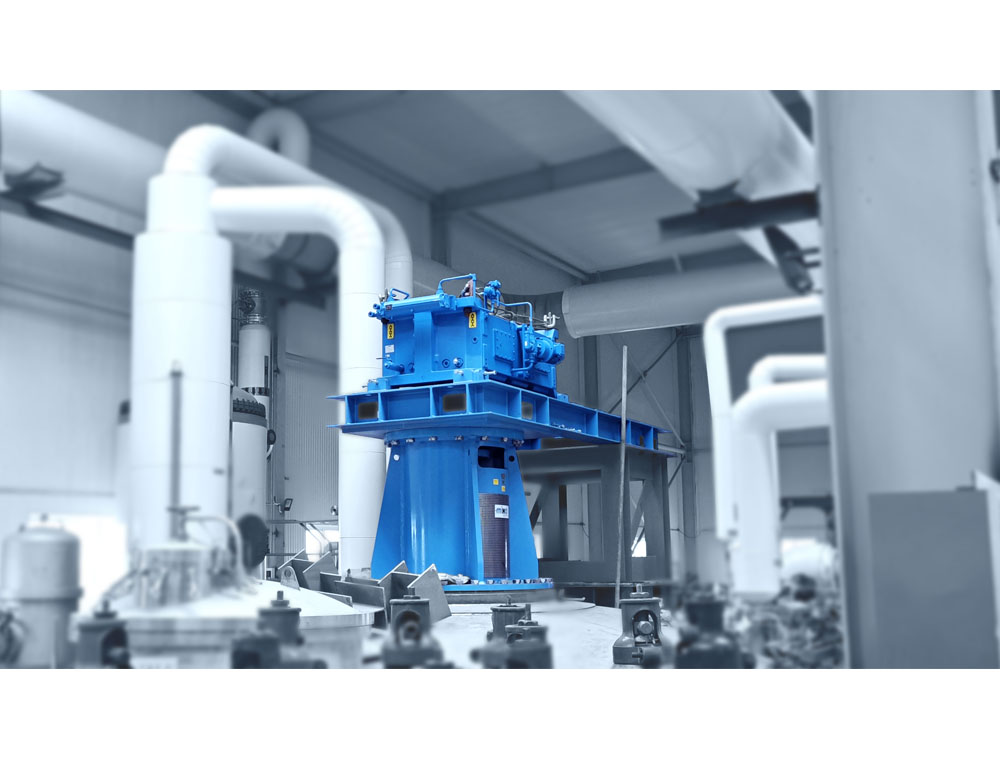

In 2023, MIXEL entered into a deep collaboration with a leading company in the precipitated fumed silica field, participating in the construction of its newly added

10,000-ton-grade silica project. In this collaboration, leveraging its professional expertise and extensive experience, MIXEL provided the customer with a full suite

of mixing equipment covering reaction vessels and steel structures, while also being deeply involved in the planning of the civil engineering design.

Through precision engineering coordination, MIXEL not only ensured seamless integration across all project phases but also saved valuable time for the customer. This collaborative milestone demonstrates that products manufactured at MIXEL's Tianjin facility in China have once again established an exemplary benchmark application in the high-viscosity materials sector, fully showcasing MIXEL's exceptional engineering design capabilities.

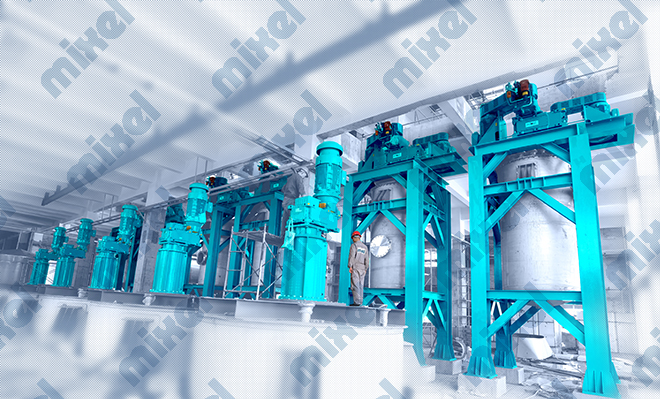

It is worth mentioning that this project is specially equipped with multiple sets of MIXEL's Agitators with Counter-rotating Twin Movement (CONTRAMIX®). Leveraging decades of technological refinement, this series of equipment delivers exceptional wear resistance, silent operation, and hygienic-grade leak-proof performance. These advanced features, combined with overall stability, provide a rock-solid foundation for the most critical stages of the production process, enabling users to achieve highly efficient and superior production outcomes.

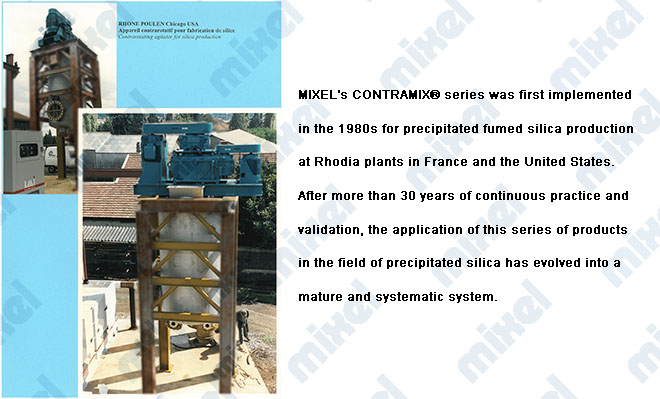

CONTRAMIX®Product History

CONTRAMIX®Product Overview

On the expansive stage of industrial production, the agitator with counter-rotating twin movement stands as a metaphorical emerging star—this integrated mixing solution plays a critical role that cannot be replicated. The uniquely engineered apparatus comprises two bidirectional coaxial shafts, each mounting impellers with opposed rotational directions, constituting an exceptional structural solution. Operating along an identical axis, these coaxial shafts rotate synchronously or alternately like precisely coordinated components, thereby executing highly efficient and precise shearing and mixing operations on materials.

The advantages delivered by this ingenious design are remarkably significant. During the mixing process, it ensures high-viscosity substances no longer "remain" stubbornly on container walls, offering an effective solution to wall adhesion problems. Simultaneously, it drives accelerated axial flow of the central material, ensuring more homogeneous blending. This effectively prevents localized overheating and mixing inhomogeneity, thus ensuring consistent product quality. Moreover, the agitator with counter-rotating twin movement significantly enhances mixing efficiency while substantially accelerating the blending rates of all components.

For industrial production, time equates to revenue, while efficiency dictates competitiveness. The agitator with counter-rotating twin movement has not only streamlined production processes but also mitigated overhead costs, ultimately delivering tangible economic benefits to enterprises. With its exceptional performance and innovative design, it has rightfully emerged as a pioneering force in industrial mixing technology, propelling production processes toward new heights of efficiency and quality.

Background of Precipitated Fumed Silica Manufacturing Process

Mixing Requirements

Homogenization, blending, solid-liquid emulsification, and precision pH control etc.

Key Metric

Silica solids content、liquefaction efficiency.

Silica solids content and dispersion uniformity are critical KPIs for precipitated fumed silica production. Each 1% increase in solids content within the liquefaction reactor reduces specific energy consumption in downstream drying, directly lowering operational costs.

Process Direction

The liquefaction process for precipitated fumed silica currently has two predominant process routes: batch production and continuous production.

Technical Challenges

High viscosity (up to 100,000 mPa·s) and high solids content.

The mixing process within the liquefaction reactor is exceptionally complex. The agitator must simultaneously ensure thorough mixing and circulation of the high-viscosity slurry medium while delivering high-speed shearing action to break down filter cake aggregates. This shearing disrupts larger crystalline structures, promoting secondary crystallization to achieve a final product with reduced particle size and enhanced uniformity.

CONTRAMIX®Key Technical Features

Leading Solid Content Indicator

Currently, the MIXEL Agitator with counter-rotating twin movement achieves a solid content of 24-25% in practical fumed silica production, establishing an industry-leading benchmark.

Ensures High-efficiency Production

The MIXEL Agitator with counter-rotating twin movement enables continuous processing of fumed silica slurries. Its superior liquefaction efficiency and multi-stage reactor train design facilitate true continuous production (simultaneous feeding/discharging), enhancing enterprise productivity while ensuring the stability of product quality.

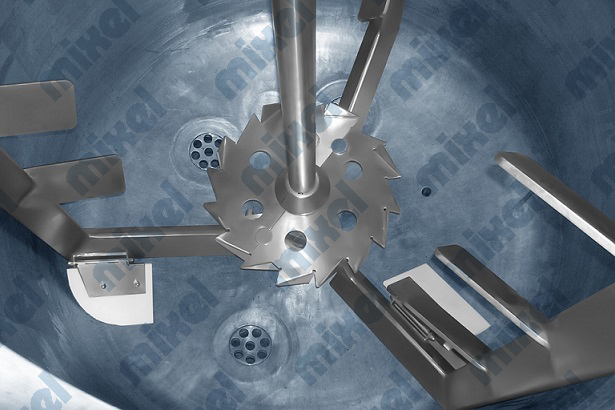

Unique Wall-Scraping Design

MIXEL's proprietary full-vessel scraping system features continuous non-metallic blades mounted on grid impeller arms extending to the reactor base, drastically reducing material buildup on vessel walls. This structural design and application demand not only exceptional engineering capabilities, but also stringent manufacturing standards and precision assembly workmanship.

For other materials, MIXEL optionally provides metallic or non-metallic scraper blades tailored to specific process requirements.