2025-06-26 15:33:09

Angola Project Pre-inspection Meeting Successfully Concluded | Project Progress Reviewed by Seven Parties Showcasing China’s Manufacturing Strength

MIXEL has successfully won the bid for the Angola Lobito Refinery Project. Swivel Side-entry agitators boosting energy infrastructure development.

In September 2024, MIXEL successfully won the bid for the Lobito Refinery Tank Farm 44# Agitator Project in Angola. MIXEL will supply a batch of Swivel Side-entry agitators for the refinery, to be installed in seven 50,000m³ and two 8,000m³ large storage tanks. This achievement underscores that MIXEL has once again gained renewed recognition for its technical expertise and market competitiveness in the international energy equipment sector.

PIM

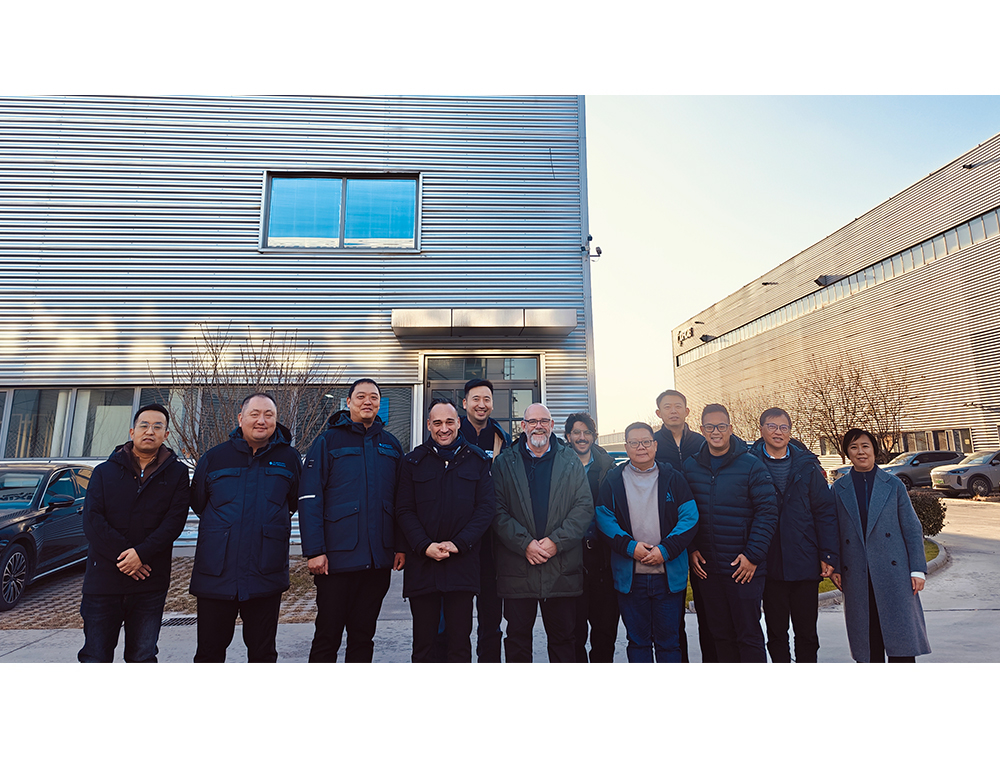

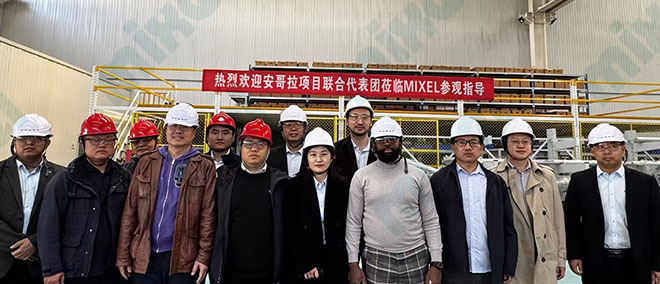

On March 21, 2025, the pre-inspection meeting for the core equipment of the Lobito Refinery Project in Angola—the Swivel Side-entry agitators were successfully held at MIXEL. Representatives from seven key stakeholders including Sonangol, KBR(PMC), CNCEC, TGC, CCESCC, CEI, SGS(TPI)gathered to review key manufacturing milestones and conducted in-depth on-site inspections at the manufacturing facilities. This meeting marks the entry of this major China-Africa cooperation project into its substantive implementation phase.

Project Background

Boost energy infrastructure development in Africa and deepen international cooperation

The Lobito Refinery in Angola is a strategic energy infrastructure project in West Africa, aiming to enhance the country's domestic crude oil processing capacity, reduce dependence on imported refined petroleum products, and drive regional economic development. The project is expected to significantly improve the local energy mix upon completion, while adding new achievements to the Belt and Road cooperation between China and Angola. The Swivel Side-entry agitators undergoing this pre-inspection, as one of the core process equipment in the refinery, has attracted keen attention from all parties regarding its technical standards and delivery schedule.

Representatives from seven parties jointly formulate the project blueprint

The conference gathers representatives of top global companies and technology institutions

Owner:SONANGOL

PMC:KBR

General Contractor and Construction Party:CNCEC、TGC、CCESCC

Designer:CEI

TPI:SGS

All parties engaged in in-depth discussions on core issues such as equipment manufacturing progress, quality control, and delivery schedules, and reached consensus on technical details, laying a solid foundation for subsequent production and installation.

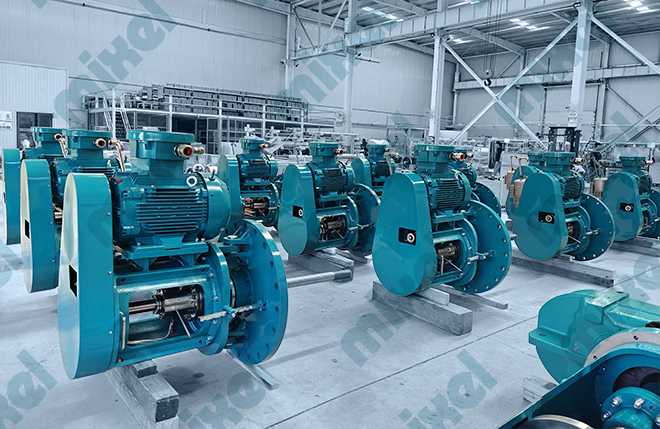

China’s manufacturing strength gains international recognition

After the meeting, representatives from seven parties visited the MIXEL production workshop. The standardized workshop, strict quality control system, and self-developed core technology of side-entry agitators earned high praise from the conference experts. SONANGOL Process Engineer Bismarke Jose stated: "The remarkable efficiency and meticulousness of China’s Manufacturing are truly impressive. We are fully confident in the timely delivery of the project."

Meeting Outcomes

Confirmation of Critical Milestones,Step Up Cooperation

After thorough discussion, all parties have confirmed the key milestones for equipment manufacturing and acceptance criteria, and reached a consensus on the subsequent installation and commissioning plan. The KBR project leader stated: "This pre-inspection meeting serves not only as a technical briefing but also as an exemplar of multiparty collaboration, providing strong assurance for the overall advancement of the project."

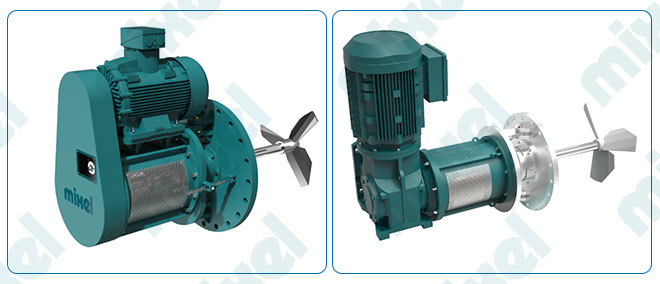

SIDEJET-S Swivel Side-entry Agitator

Technical Highlights

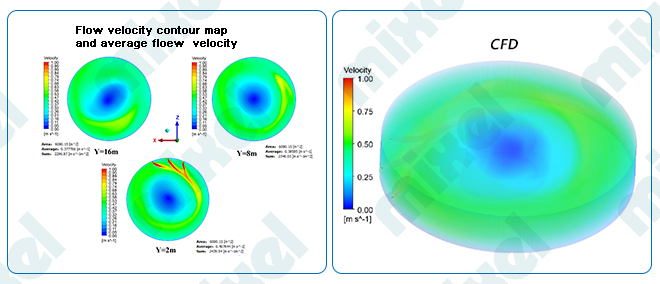

#01-Dynamic Mixing · Full Tank Coverage

Swivel Side-entry design: The equipment adopts horizontal installation on the sidewall, eliminating structural risks associated with tank top/bottom penetration.

Equipped with a motor-driven Swivel mechanism (with a swing angle of ±30°), it enables three-dimensional mixing.

Jet disturbance intensification technology: The system employs high-efficiency axial-flow blades, combined with high-speed jet flow and wide-range swivel,

to completely eliminate "dead zones" within the tank, ensuring uniform distribution of crude oil components and reduced sedimentation.

#02-Multiple seals, on-line replacement

In addition to conventional mechanical seals, the swivel mechanism adopts a 2+1 sealing system (two active seals with one standby). This design enables online

replacement upon O-ring aging, preventing persistent leakage after failure or the need for tank cleaning during maintenance, thereby ensuring continuous on-site operation.

#03-Corrosion-Resistant, Long Service Life, Safe and Reliable

Special Material Application: The main shaft is made from duplex stainless steel 2205, which resists corrosion from sulfur-bearing crude oil, enabling extended service life.

Looking to the future

设备应用于外蒙古炼油厂The equipment was used in an oil refinery in Mongolia

(factory photographed in May 2025)

The successful conclusion of this pre-inspection meeting marks the beginning of the final countdown period for equipment delivery in the Lobito Refinery Project in Angola. As a flagship example of China's high-end equipment "going global", this project not only demonstrates the technological prowess of Chinese manufacturing, but also serves as a vivid practice of China-Africa production capacity cooperation and the joint construction of the Belt and Road Initiative. All parties expressed their commitment to enhancing collaboration and ensuring the high-quality implementation of the project, thereby propelling the development of Africa's energy industry.