2025-12-11 10:09:28

Over 40 Years of Expertise in Fluorine Chemical Industry | MIXEL Has Earned Global Trust with Its Professional Mixing Solutions.

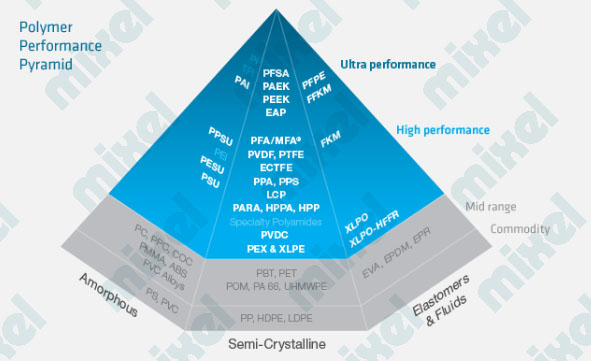

In the field of new materials for the chemical industry, fluorine chemical industry is hailed as a "golden industry ". Its products are widely used in high-end industries such as military, automotive, semiconductor, and new energy sectors. Behind this high value-added industry, mixing equipment, serving as the "heart" of the reaction process, plays a crucial role in production safety, efficiency, and cost control.

As a leader in mixing technology, MIXEL has maintained strategic collaboration with Belgian chemical giant Solvay (SOLVAY) since 1980. Over the past four decades, MIXEL has consistently specialized in fluorine chemical industry—the "golden industry "—delivering customized solutions for extreme-temperature, high-pressure corrosion, and other complex operating conditions through extensive participation in global premium chemical projects. This expertise has established the company as a benchmark for industrial technical standards.

Extreme Operating Conditions: Stable Operation Under High Temperature and High Pressure

In the synthesis processes of PVDF/FKM and other fluorinated polymer materials, the reaction conditions are extremely harsh—with a design pressure as high as 170 bars and a wide operating temperature range from 5°C to 120°C. Under these combined high-temperature and high-pressure conditions, conventional equipment faces a high risk of leakage due to seal failure, directly threatening production safety and plant stability.

MIXEL, with over 40 years of R&D experience in fluorine chemical specialty equipment, has successfully addressed this industry pain point through specially designed mechanical seals and lubrication systems. In actual operation, the equipment has achieved continuous and stable operation for more than 10 years without any leaks, demonstrating outstanding reliability.

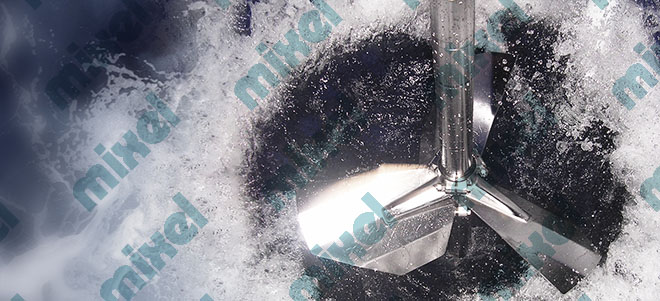

Efficiency and Energy Saving: The True Test Lies in Impeller Design

Efficient Mixing

MIXEL achieves efficient and uniform material mixing through its fluid-optimized impeller design. Combined with its excellent mechanical sealing and lubrication system, the overall production efficiency is significantly enhanced.

low-power Operation

With over 50 years of mixing technology expertise, the MIXEL impeller design achieves an optimal balance between high-efficiency mixing and low energy consumption, helping customers reduce costs and improve efficiency.

Easy to Maintain

The unique JET maintenance-free frame design allows for quick replacement of sealed bearing components without disassembling the motor reducer, significantly reducing downtime.

End-to-end Technical Assurance: Excellence in Design and Manufacturing

Throughout the product research, development, and manufacturing processes, MIXEL consistently upholds high standards and strict requirements:

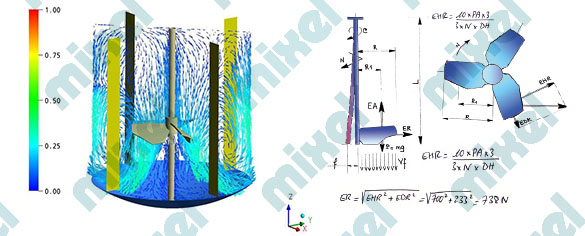

Fluid and Mechanical Design

Through methods such as Finite Element Analysis (FEA), Kinematics and Stress Analysis, and Resonance Frequency Analysis, we ensure that every device withstands dual validation from both theory and experiment.

Processing and Manufacturing

European technicians uniformly review the drawings, implement unified production standards, quality control, and factory inspection processes to ensure product consistency.

Supply Chain Management

Strictly select raw material suppliers, establish a sound supplier management system, and ensure product quality from the source.

Service First: Full-Lifecycle After-Sales Support

MIXEL believes that high-quality products cannot do without professional services.

Always Adhere to

Technical disclosure materials will be provided immediately after the contract is signed.

Provide dedicated non-dismantling maintenance tools.

Provide remote or on-site installation guidance and training.

The quick service mechanism is established with "12-hour response, 24-hour solution proposal, and on-site arrival within 72 hours if necessary.

Provide free follow-up visits and equipment inspection services on an irregular basis to ensure long-term stable operation of the equipment.

In the technology-intensive fluorochemical industry, MIXEL has become the preferred partner for numerous global chemical enterprises, leveraging its profound technical expertise, reliable product performance, and comprehensive service support. Moving forward, MIXEL will continue to drive innovation, propelling the fluorine chemical industry toward a new stage of higher-end, safer, and more efficient development.