2025-08-11 16:02:24

Powering a Green Future | MIXEL's Global Eco-Contribution: 300+ Anaerobic Digester Agitators

Transforming urban food waste into renewable power

In 2019, during the expansion project for food waste treatment in Nanhai, Foshan, Grandblue Environment faced significant challenges. At this critical juncture, they chose MIXEL, a partner with years of deep expertise in the anaerobic digestion field. Starting with the Nanhai project, the collaboration between the two parties deepened continuously. MIXEL's high-performance digester agitators became a key driver for multiple projects' stable and efficient operation, laying the foundation for their ongoing collaboration.

Leveraging precision-engineered docking, MIXEL not only ensured seamless integration across all project stages but also significantly reduced the user's valuable time investment. This collaboration rapidly set new benchmarks in the anaerobic digestion of organic waste sector, demonstrating MIXEL's exceptional engineering expertise.

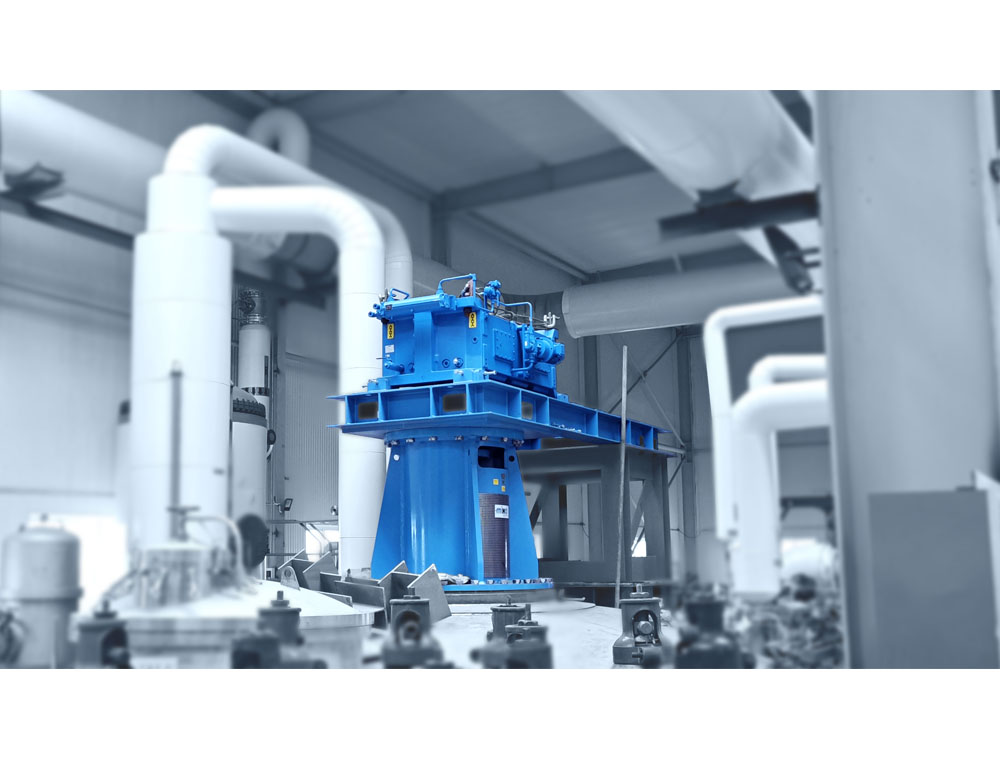

The MIXEL DIGIMIX® top-entry agitator which is a flagship product deployed in the project has evolved through decades of technological refinement. With advanced performance and ultimate reliability, it ensures operational stability in critical processes, continuously enabling efficient, high-quality production.

Half a century of mixing expertise

Images of Customer Certifications and Equipment On-Site Provided by KDM Korea, Demonstrating Global Trust and Capability.

Since 1969, specializing in mixing technology, MIXEL has consistently driven innovation and underpinned quality. Driven by a relentless pursuit of technical excellence and continuous exploration, the company has successfully delivered over 300 high-performance anaerobic digester mixers worldwide. Notably, the largest anaerobic digester agitator boasts a unit capacity of 12,000m³. Since its successful commissioning in 2015, this critical asset has demonstrated sustained operational excellence.

Combining over 55 years of specialized mixing expertise with nearly a century of mechanical engineering heritage, MIXEL has established an unassailable position as the expert in anaerobic mixing technology. MIXEL solutions are extensively applied across energy, environmental protection, and agricultural sectors, providing enduring reliability for global biogas plants and anaerobic digestion projects. Those ceaselessly turning impellers are, in essence, the vital strokes defining the circular economy era.

DIGIMIX® Top-entry agitators: The essential component for anaerobic processes

Rock-solid stability Zero-hassle operation

Vertical top-mounted central installation ensures superior reliability; minimal maintenance requirements with online maintenance capability significantly enhance production continuity.

High-efficiency Cost-optimized

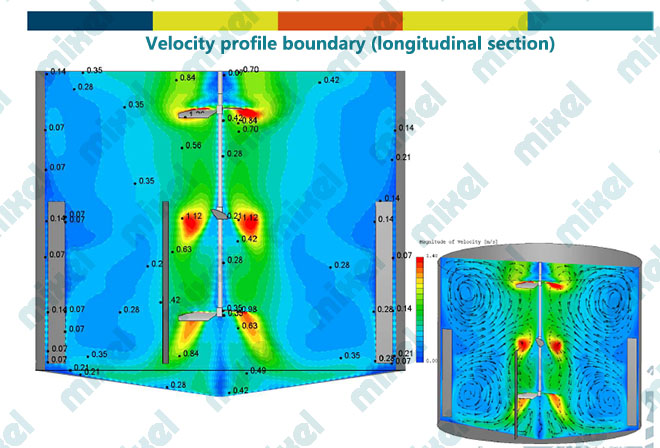

Unique impeller fluid dynamics design significantly reduces energy consumption, enabling greener and more cost-effective operation.

Rapid homogenization Stable temperature control

Accelerated in-vessel blending achieves thermal equilibrium, eliminating vertical temperature stratification.

Break surface scum Prevent material caking

High-intensity vertical recirculation mobilizes scum layer radially and axially, completely suppressing crust formation at vessel crown.

Jet-force scouring Settled grit terminator

High-volume, high-velocity internal circulation flow virtually eliminates grit accumulation in tank dead zones.

SmartShield safeguarding Security evolution

Automated hydraulic seal monitoring proactively prevents biogas leakage, delivering next-generation safety assurance.

Process fundamentals-Why vigorous mixing is imperative in anaerobic digestion?

In the anaerobic digestion process converting organic waste into clean energy, mixers serve as mission-critical "dynamic drivers ".

Core requirements

Enhancing microorganism-substrate exposure to achieve homogeneous mixing, thermal transfer, and pH modulation while mitigating large-scale sedimentation and scum encrustation.

Key process indicators

Total solids (TS), temperature, pressure, pH, fermentation microbiota composition, VFA (Volatile Fatty Acids) inhibitor concentration.

Process route selection

Current mainstream processes include batch production and continuous flow production.

Core challenges - High-solids media

When processing viscous feedstocks with high solids content, agitators must maintain functional integrity under extreme operating conditions to ensure:

Complete material mixing recirculation

Long-term stable operation of equipment

Precisely balancing microbial exposure and biochemical reaction time.

Maximize volumetric gas production efficiency

MIXEL other product series in anaerobic digestion industry

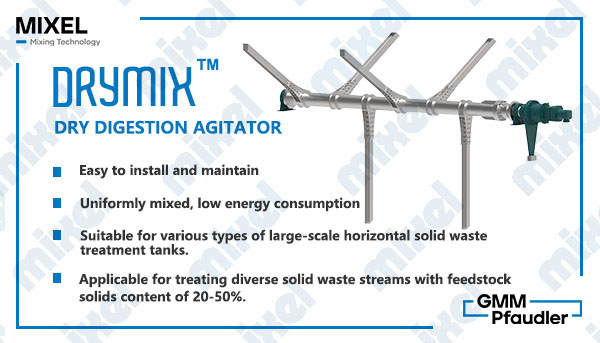

01 Dry agitator

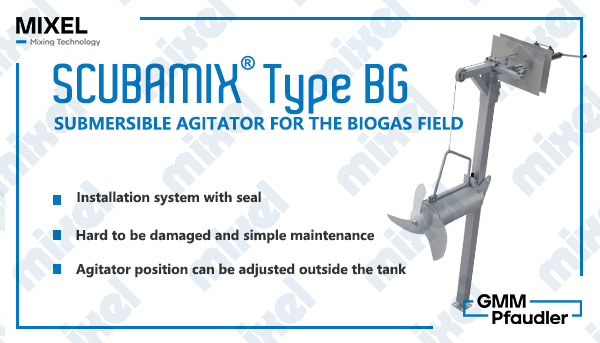

02 Submersible Agitator

03 Side-entry Agitator

Spin turbines, propel a sustainable future

MIXEL's anaerobic agitation technology has become a critical pillar in green energy production, with its exceptional performance and broad applicability successfully implemented in over 300 specialized installations worldwide and numerous cutting-edge fermentation projects. Each steadily operating DIGIMIX® agitator continuously reduces greenhouse gas emissions while unlocking and converting the intrinsic energy potential of waste, forging novel pathways for energy looping utilization.