2025-08-19 10:58:20

New Energy-Saving Breakthrough for Kiloton Fermenters | MIXEL Agitation Tech Boosts Efficiency by 20%.

1000m³ Super Large-Scale Glutamic Acid Fermentation Project

As the bio-fermentation industry rapidly advances towards larger scale and higher efficiency, 1000m³ fermenters are becoming the new industry benchmark. However, this increased scale also introduces core challenges such as mixing homogeneity and energy consumption control. As a solution provider pushing the boundaries of fermentation technology, MIXEL leverages over 55 years of agitation design expertise to successfully empower facility owners in achieving energy-efficient glutamic acid production within these ultra-large 1000m³ vessels. Verified results demonstrate nearly 20% energy savings, driving the next wave of technological innovation in the industry.

Fluid Flow Design Challenges in Large Fermenters

After fermentation tank capacity exceeds 600m³, traditional stirring configurations face three major bottlenecks:

01. Mixing inhomogeneity

Non-uniform gas-phase dispersion, inadequate oxygen transfer, and pronounced tendency for solid-liquid phase separation

02. Surge in energy consumption

Imbalance between impeller diameter (d/D ratio) and rotational speed ;

03. Performance variability

Significant differences exist in gas dispersion and mass transfer performance between different manufacturers under the same operating parameters.

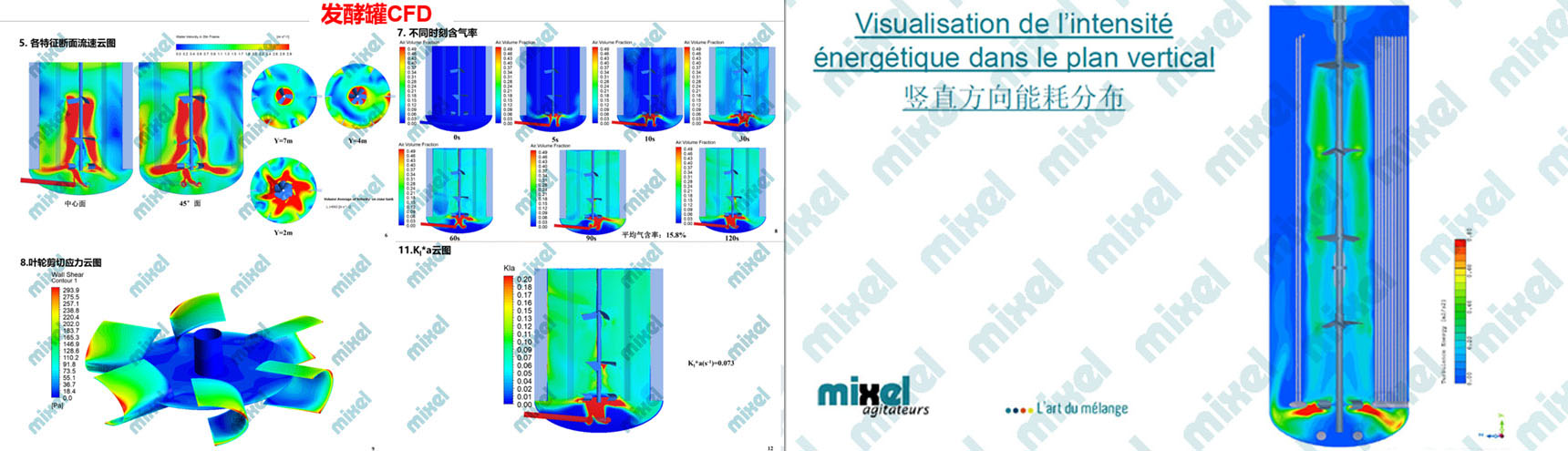

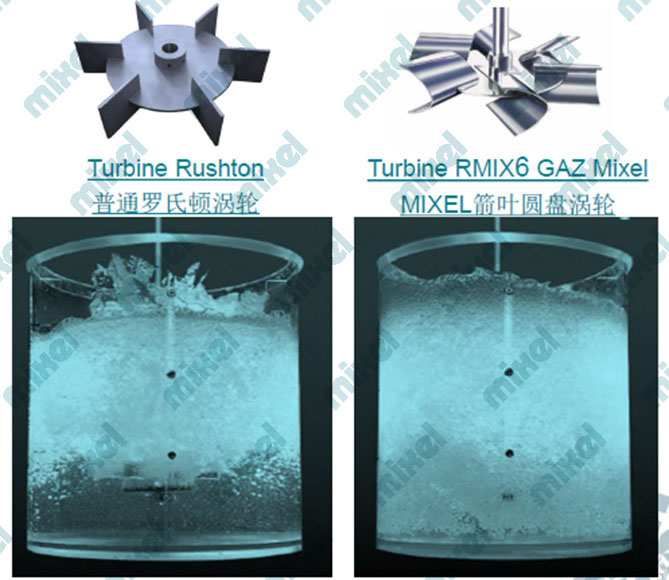

MIXEL Solution

Independently designed for each tank, impeller spacing, diameter, and rotation speed combinations are precisely verified through CFD fluid simulation, achieving power prediction accuracy exceeding 97%.The patented impeller system balances high discharge capacity with low energy consumption, completely overcoming mixing bottlenecks in large tanks.

Real-world Data: 20% Energy Savings Verified with Rigorous Testing

In the 1000m³ glutamate fermenter project, MIXEL redefined industry standards through technical superiority.

Power design

Breaking away from conventional design, MIXEL adopts more energy-efficient motors.

Test results

Operating at 20% lower power than peer systems, yet achieving superior agitation performance.

Core support

The patented high-efficiency impeller enhances pumping capacity while reducing energy consumption. For Smith's application, it elevates dispersion effectiveness and oxygen transfer rate.

Mechanical Design- Eliminating Risks at the Source

Components | Innovative Design | Solve Pain Points |

Coupling | Hygienic design | Mitigation of cavity pooling risks |

Impeller connection assembly | Significantly reduce interface gaps, corrosion prevention in welds | |

Bottom bearing assembly | Significantly reduce dead zones, rapid drainage |

From fluid simulations to mechanical innovation, MIXEL redefines efficiency standards for large-scale fermentation tanks through proprietary design capabilities. The successful implementation of 1000m³-scale projects not only validates its energy-saving expertise but also propels the industry toward a greener and more efficient leap forward.